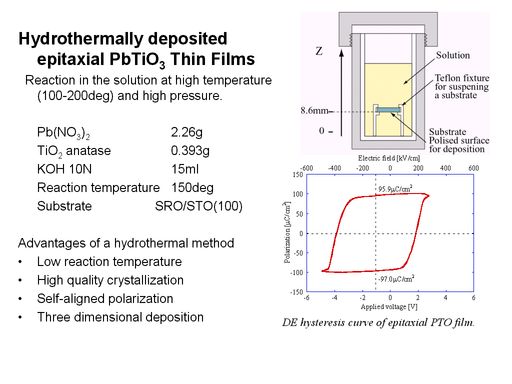

We are studying lead titanate (PbTiO3) thin film for ferroelectric medium of SNDM data storage system. For this application, uniform ferroelectric properties in nano-scale order because data-dot size is nano meter range. There are many methods to deposit ferroelectric films, for example, sputtering, sol-gel method, chemical vapor deposition; and in these all methods, a crystallization process; upper than 600 degree treatment, is indispensable. In contrast, a hydrothermal method enables extremely low temperature deposition of 150 degrees; then the good crystallization quality and the easy chemical component control are realized. We succeeded in depositing an epitaxial lead titanate thin film using a SrRuO3/SrTiO3 (100) single crystal substrate.

Lead titanate is very important perovskite material that is used as one component of PZT and relaxor type ferroelectrics. However, since the discovery of lead titanate in 1950, it has been believed to be quite difficult to measure the ferroelectric properties of lead titanate due to its large conductivity and large coercive field. However, in our study, very nice DE hysteresis curve of a hydrothermally deposited lead titanate thin film was realized at the first time. Low reaction temperature results in overcoming the lead vacancy problem and the good crystal quality is thought to contribute good ferroelectric properties. The remanent polarization was 96.5mC/cm2, which is larger than theoretically predicted value of 81mC/cm2. The DE hysteresis curve shape indicated the film crystal quality is closed to single crystal. Furthermore, SNDM observation revealed that this film has perfectly c-axis oriented and was composed of uniform ferroelectric material even in sub-nanometer scale.

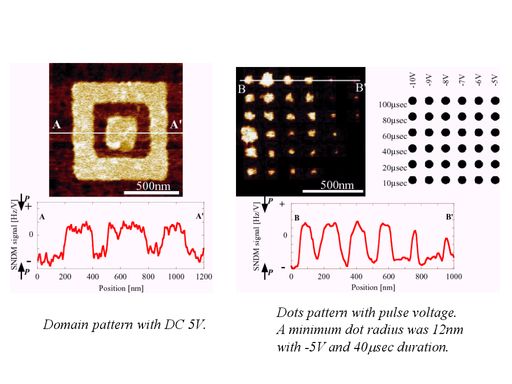

The poling direction of this film was controlled using a conductive AFM cantilever probe. By scanning the AFM lever with plus of minus DC 5V applied voltage, the domain pattern was carried out. This result indicated that the all parts of the film can be utilized as the ferroelectric data storage medium. Subsequently, pulsed voltage was applied with various parameters, and nano dot pattern was made. With the voltage of -5V and 40 usec, the dot radius was 12 nm corresponding to data storage density of 1Tbit/inch2. Now, we are trying to higher density data storage by improving the thin film quality.